The Reorder Stock function can help you reorder your stock when you need more inventory. You’ll need to set up your reorder points and quantities first before inFlow can reorder stock for you. This article covers three sections you can click on the links below to skip to them.

- What does reorder point and reorder quantity mean?

- How should I set up my reorder points/quantites for items I don’t stock / other special cases?

- Why isn’t my product showing up in the reorder stock window?

What does reorder point and reorder quantity mean?

The reorder point field is the minimum level/point of your stock before you need to reorder more. So if you set a reorder point of 25, as soon as the stock level goes to 24 or lower, inFlow will suggest that you reorder it.

The reorder quantity field is how much stock you would like to reorder at a time. For example: if you always purchase the item in cases of 4 units, then you’ll want to put 4 in the Reorder Quantity field. inFlow will multiply the reorder quantity in the purchase order as needed to get you back up to above your reorder point.

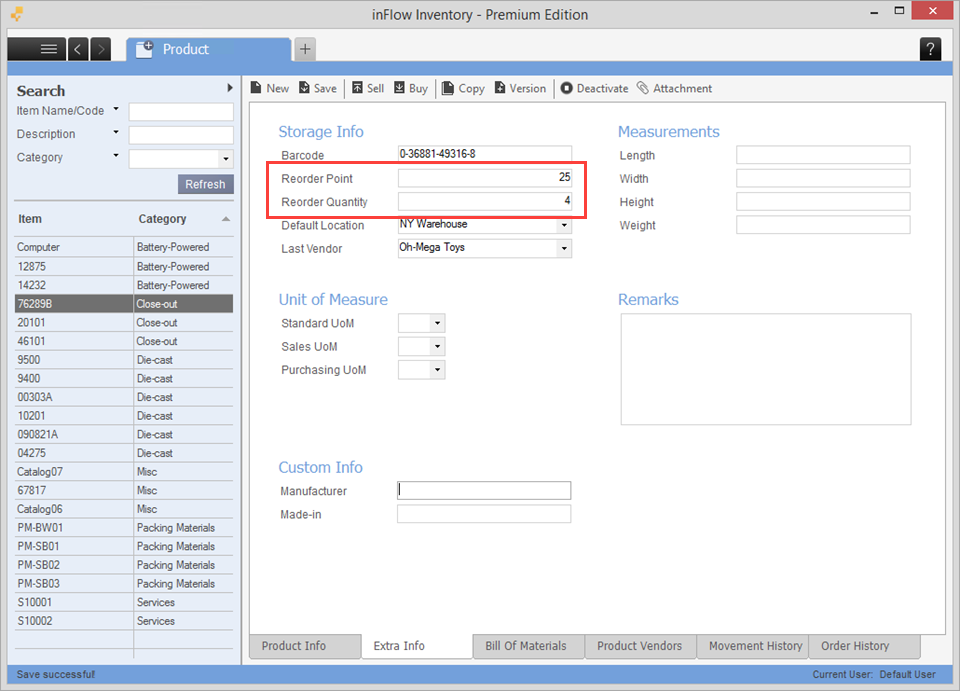

To set up your reorder points/quantities:

- Go to your product record.

- Click the “Extra Info” tab.

- In the “Reorder Point” field, enter the minimum point/limit your stock level would reach before reordering more.

- In the “Reorder Quantity” field, enter the amount to reorder at a time if the item needs to be restocked.

- Click to Save your record.

Need help figuring out how much stock you should set your reorder point to? Check out the inFlow blog for more information: www.inflowinventory.com/blog/safety-stock-calculation

For example:

If I have an item that I order in sets of 4, I would want inFlow to always order at least 4 (reorder quantity) when I reorder. Let’s say I want to have at least 25 in my warehouse at all times (reorder point). So I would set up my reorder points and reorder quantities as above.

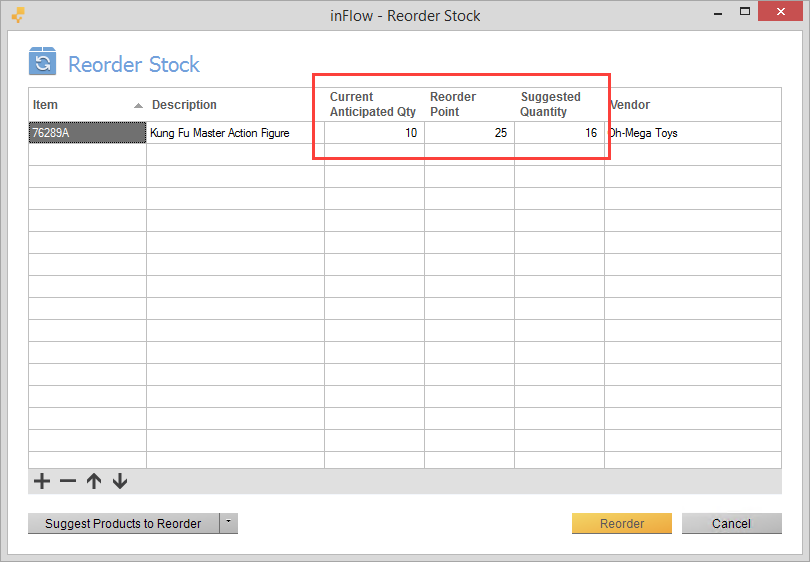

As the reorder point is 25, it will ask me to reorder as much as possible to get back to 25 or above. So for example: if the stock level was 10, the system would look at the difference between that and your reorder point (25-10 = 15). Since we have a reorder quantity of 4, it must use multiples of 4 to get you back up to 25 or above. So instead of ordering 15, it orders 16 (i.e. 4×4).

To reorder:

- Go to Main Menu > Inventory > Reorder Stock.

- Click “Suggest Products to Reorder” to see the suggested list of items.

- Review the list and set any vendors where necessary. When you’re ready click “Reorder” to automatically generate your Purchase Orders (split by Vendor).

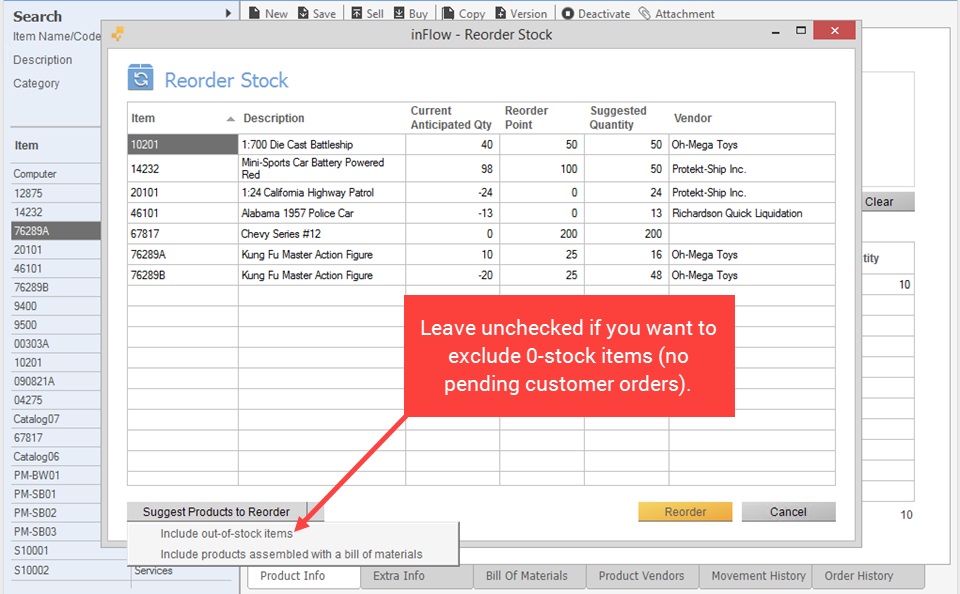

To control what the system suggests you reorder:

- In the Reorder Stock window, click the arrow beside the “Suggest Products to Reorder” button.

- You will see two options that you can turn on or off:

- Include out of stock items: if this is checked then inFlow will also suggest you reorder products that are at 0 quantity and reorder point set to 0. Simply uncheck this option if you only want to reorder items that have outstanding orders, instead of including anything that you’re not currently stocking at the moment (see more below)

- Include products assembled with a bill of materials: if this is checked, inFlow will suggest you reorder items that you can assemble yourself. Use this if you need to have another manufacturer assemble some of your products for you due to time constraints.

Current Anticipated Quantity

The reorder stock screen also lists the Current Anticipated Quantity for your items. This number is determined by what you’d have in stock if all your sales and purchases were completed now.

When your current anticipated quantity is lower than your reorder point, inFlow will suggest that you reorder more stock. For more information on how current anticipated quantity is calculated please take a look at this article.

How should I set up my reorder points/ quantities for items I don’t stock?

Generally, you would want to set your reorder point to a level where you can still fulfill incoming orders. You should plan this with how long it takes for your vendor to send you the stock. It’s also a good idea to set a large reorder quantity to so you don’t keep sending out purchase orders too often.

However, there may be some special cases where this doesn’t apply. For example, products that you don’t keep in stock, but only order when necessary. You may also have stock you only want to keep exactly at or just above the reorder point.

- To have inFlow reorder items up to just slightly above the reorder point, set your reorder quantity to a low number (3, or 4).

- To have inFlow reorder items up to exactly the reorder point, set your reorder quantity to 1.

- To have inFlow exclude items at 0 stock, but only reorder when a customer orders from you, set your reorder point to 0. In the reorder screen, make sure to always have “Include out-of-stock” items unchecked.

Why isn’t my product/vendor showing up in the Reorder Stock window?

If you don’t see your product listed here, it could be that your current anticipated quantity is higher than your reorder point. Common reasons would include:

- you’ve already got a purchase order/work order incoming for this product so you don’t have to reorder more

- the product is a final assembly/kit that can be created out of your components, and your reorder stock window is set to exclude assembled products

As for the vendor column, inFlow auto-selects the last vendor you purchased the item from. If you have multiple vendors for an item, this selection may change during each re-ordering. It’s best to review the list every time you reorder. A blank vendor field means that the item has never been ordered in any purchase order before.